View Mobile Number

Mica Heaters

Leading Exporters and Wholesaler of Mica Band Heater, Mica Disc Heater and Mica Strip Heater from Chittorgarh.

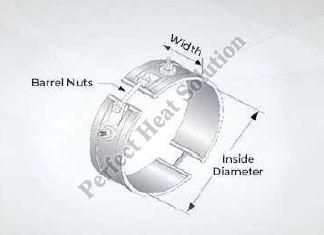

| Business Type | Exporter, Supplier |

| Material | Steel |

| Finishing | Well Finished |

| Material Grade | SS 304 |

| Condition | New |

| Power Source | Electric |

| Application | Industrial Use |

| Thickness | 4-16 Mm |

| Minimum ID | 40 mm |

| Minimum Width | 40 mm |

| Maximum ID | 1200 mm (3-PART) |

| Maximum Width | 900 mm |

| Power Supply | 24 V up to 480 V |

| Wattage | 50 W Inch Square 127 W Per Cm Square |

| Connection Type | Series/Parallel |

| Sheathing | Stainless Steel, Galvanized Aluminum |

| Maximum Temperature | 550 °C |

| Heating Element Grade | Ni: Cr (80:20) |

| Wire Termination Style | Customize |

| Cut-out & Hole | As per Customize |

| Lead wire Type | Fiber Glass. Teflon Lead wire, Braiding |

| Terminal Box | As per Customize |

| Connector | As per Customize |

| Watt Density Calculation in Cm Sq | (Wattage)/ {(ID*Width*3.14285)/ (2.54*2.54)} |

| Watt Density Calculation in Inch Sq | (Wattage)/ {(ID*Width*3.14285)/ (25.4*25.4)} |

| Ceramic Knuckle Type | High Grade |

| Insulation | As per Customize |

| Note | Customized Product Available as per Requirement |

| Outer Part Material | Stainless Steel Grade(SS304, SS316, SS321 & SS310), Incoloy 600, Incoloy 800, as Per Application Temperature requirement. |

| Shape | As per customized requirement. Square, L, U, W etc |

| Voltage | 240V, 400V-415V |

| Phase | 1-Phase, 2-Phase& 3-Phase |

| Power | As per customized |

We are supplier of these types of heating element in this segment which can be wrapped around cylindrical surface in easy form. We would like to express our strength that we are already supplying these types of special heating element for research fields with super quality.

Mica Band heaters are efficient and economical solutions to the heating requirements of many applications. Mica Band heaters can attain a maximum sheath temperature of 900°F, but with different electrical termination styles, clamping mechanisms, and ability to accommodate holes and cutouts, mica band heaters are successfully used in many applications, but are mostly sought for in the plastics industry.

The Mica Band Heaters made by Perfect Heat Solution utilizes different types of Top-Grade Mica. The thickness of each mica layer is carefully selected in order to balance between the insulating characteristics of mica and the ease of heat transfer from the heating core to the machine barrel.

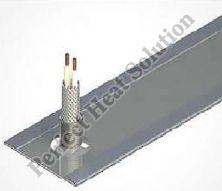

We are offering below such kind of Strip heaters with different Parameters.

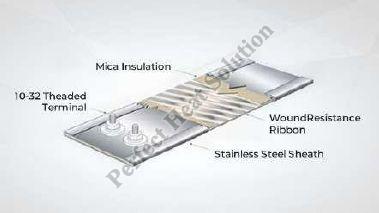

Construction

Mica Strip Heaters are manufactured to your custom specifications. They feature a high-temperature oxidation SS sheath and high-grade mica insulation resistant to moisture and high temperatures. Nickel/Chromium resistance wire evenly would provide for uniform and reliable heat distribution.

Mica Strip Heaters are constructed by winding a nickel-chrome resistance wrapped around Centre mica insulation and covered in a stainless-steel, Galvanized, Aluminized, MS sheath. They are available in an extensive variety of sizes and shapes with options for holes, notches, and cut-outs. A number of threaded terminals, wire lead options, and terminal boxes offer great flexibility for field wiring. These heaters are ideal for plastic processing applications and for anywhere heat is needed on a flat or curved surface.

Features :

- Clamping straps will assure efficient heat transfer.

- The low mass design allows quick heat-up and a quick response.

- Our design variations provide convenience and heater protection.

- High quality Mica having excellent Dielectric strength.

- Specific watt density: 3.5 W/cm2

- Working temperature up-to 550°C

- Element: Nichrome strip/wire

Applications :

- Injection Moulding Machine

- Container, pipe, or tank heating

- Applications in the food industry

- Pharmaceutical applications

- Blow Moulding Machine

- Plastic extrusion

- Extrusion Line

| Business Type | Exporter, Supplier |

| Material | Mica |

| Finishing | Well Finished |

| Power | As per customised |

| Power Source | Electric |

| Application | Industrial Use |

| Certification | CE Certified |

| Frequency | 50/60 Hz |

| Phase | 1-Phase, 2-Phase& 3-Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Note | Customized Product Available as per Requirement |

| Outer Part Material | Stainless Steel Grade(SS304, SS316, SS321 & SS310), Incoloy 600, Incoloy 800, as Per Application Temperature requirement. |

| Shape | As per customized requirement. Square, L, U, W etc |

| Voltage | 240V, 400V-415V |

| Business Type | Exporter, Supplier |

| Finishing | Well Finished |

| Thickness | 5 Mm |

| Minimum Length | 20 mm |

| Minimum Width | 20 mm |

| Maximum Length | 2400 mm |

| Maximum Width | 1200 mm |

| Power Supply | 24 V up to 480 V |

| Wattage | 50 W Inch Square 125 W Per Cm Square |

| Connection Type | Series/Parallel |

| Sheathing | Stainless Steel, Galvanized Aluminum |

| Maximum Temperature | 550 °C |

| Heating Element Grade | Ni: Cr (80:20), Kanthal |

| Wire Termination Style | Customize |

| Cut-out & Hole | As per Customize |

| Lead Wire Type | Fiber Glass. Teflon Lead wire, Braiding |

| Terminal Box | As per Customize |

| Connector | As per Customize |

| Watt Density Calculation in Cm Sq | (Wattage)/ {(Length*Width)/ (2.54*2.54)} |

| Watt Density Calculation in Inch Sq | (Wattage)/ {(Length*Width)/ (25.4*25.4)} |

| Mica Type | High Grade |

| Insulation | As per Customize |

| Note | Customized Product Available as per Requirement |

| Outer Part Material | Stainless Steel Grade(SS304, SS316, SS321 & SS310), Incoloy 600, Incoloy 800, as Per Application Temperature requirement. |

| Shape | As per customized requirement. Square, L, U, W etc |

| Voltage | 240V, 400V-415V |

| Phase | 1-Phase, 2-Phase& 3-Phase |

| Power | As per customized |

It is a simple way of using surface area to transfer heat effectively. A fairly inexpensive way of heating surfaces or small areas, strip heaters is an excellent solution to meet any budget. If strip heaters are used as a radiant heater, they have can have fins to maximize surface area and heat transfer to the air.

Features :

- Heat up time is fast to provide a quick response to control input.

- The flat inner resistance ribbon generates a broad area of overall heat to put the heat source close to the work.

- Quality assembled winding and spacing of ribbon ensures maximum heat transfer and heater longevity.

- The Stainless-Steel sheath is treated so that the surface allows the increase of heat transfer to retard oxidation.

- The Mica insulation also withstands high voltage temperatures, resist moisture, and remain immune to most chemicals.

- The Aluminized Steel sheath is rust resistant, durably rigid, and generates heat well.

Mounting Suggestion :

Maximize your mica strip heater, by ensuring the following tips:

- The surface to be heated needs to be kept smooth and clean, for best heat transferring. Caution: Gaps can cause hot spotting.

- Terminal post nuts should not be over tightened, while posts should be securely riveted to the elements. Caution: Excessive torque can break the connection.

Construction

Perfect Heat Mica Strip Heaters are supplied to your custom specifications. They feature a high temperature oxidation SS sheath and high-grade mica insulation resistant to moisture and high temperatures. Nickel/Chromium resistance wire evenly would provide for uniform and reliable heat distribution. Mica Strip Heaters are constructed by winding a nickel-chrome resistance wrapped around Centre mica insulation and covered in a stainless-steel, Galvanized, Aluminized, MS sheath. They are available in an extensive variety of sizes and shapes with options for holes, notches and cut-outs. A number of threaded terminals, wire lead options and terminal boxes offer great flexibility for field wiring. These heaters are ideal for plastic processing applications and for anywhere heat is needed on a flat or curved surface.

Applications :

- Process air heating: Ovens, Drying cabinets, Baking ovens, Vacuum dehydrating ovens, Moisture protection for motors

- Dehumidifiers: Hoppers, Conveyors, Ducts, Car Heating Systems, Thawing

- Dropping resistors: Line applications in railroads and load banks

- Vulcanizing presses, Drying equipment, Laboratory equipment

- Surface heating: Dies, molds, Tanks, Piping etc.

- Packaging and sealing equipment Food warming equipment

- Space heating

- Air conditioning, Blow moulding equipment’s.